In our two previous articles, we discussed foundry supports, explaining what they are and why opting for custom-made solutions can make a difference. This article focuses on another key component in metal transformation: molds for sheet metal processing.

What is a mold?

A mold for sheet metal processing is a high-precision industrial tool used to give a metal sheet — typically made of iron — its specific shape, dimensions, and specific features through operations such as blanking, bending, deep drawing, drilling, or cold stamping.

The mold is usually mounted on a mechanical or hydraulic press, which provides the closing and forming force required for the process.

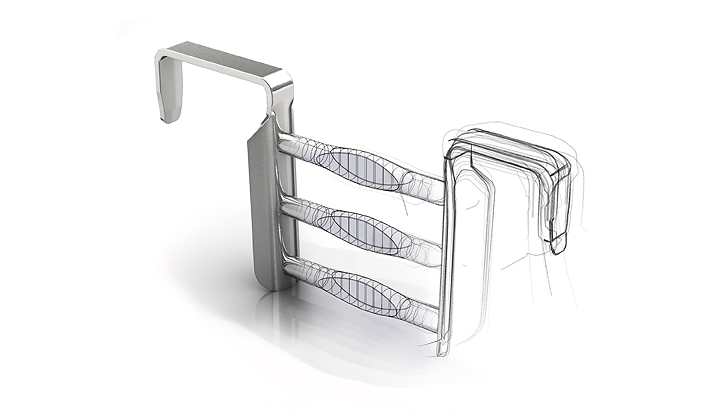

It consists of two main parts:

- The Die (lower part) serves as the base and defines the profile of the finished piece.

- The Punch (upper part) applies the necessary pressure to the sheet metal, deforming it into the desired shape.

Molds are made of special heat-treated steels, designed to withstand stress and ensure long-term durability and performance.

The importance of the mold in the production process

Designing and manufacturing a mold requires extensive technical expertise and precision. Every detail is custom engineered based on the type of sheet metal, the required tolerances, and the production volume.

In essence, the mold is what allows a simple iron sheet to be transformed into a perfectly engineered component — with speed, repeatability, and consistent quality. It’s an invisible tool to the general public, yet indispensable for almost everything made of metal.

Mold manufacturing in the foundry sector

The foundry industry requires the use of specific metal components designed for various applications, such as foundry chaplets and core supports, motor separators, locating pins, and metal filters.

These components — essential for ensuring precision and reliability in casting processes — are produced using dedicated molds and tooling, specifically designed and built for each part type.

For more complex shapes, such as core support brackets, specialized systems are employed, integrating automated presses with combined wire and strip feeding systems.

During the production cycle, the material is shaped, bent, and sometimes welded or riveted to achieve the required final geometry, while maintaining tight tolerances and dimensional consistency even in high-volume manufacturing.

Thanks to this technology, it is possible to produce robust, precise, and repeatable metal components, optimizing time, cost, and quality in line with the needs of modern foundries.

Costs and mass production

The design and manufacturing of a mold represent a significant investment. However, this cost has a lower impact when it comes to mass production.

In other words, the economic impact of mold development decreases proportionally as the number of produced parts increases. This happens because the initial tooling cost is spread across a larger number of units, effectively reducing the cost per piece.

What if the mold has already been made? The Vemek molds

With over sixty years of experience in the industry, Vemek has successfully tackled a wide range of projects and challenges. Over time, we have designed and manufactured molds of every kind, building up an extensive portfolio of ready-to-use solutions.

Benefits for the customer

For our clients, this translates into two major advantages:

- Cost reduction: thanks to the availability of pre-existing molds, there is no need to invest in new design and manufacturing processes.

- Faster production times: using ready-to-use molds allows production to start much sooner, without waiting for new tooling to be built.

Mold customization

In the foundry industry, producing unique or highly specific components is a common challenge. Standardized solutions are often not enough to meet the specific needs of a project. In such cases, the development of customized molds becomes essential.

The need for a customized approach

The design and manufacture of customized molds require specialized expertise and a deep understanding of the foundry process. For a foundry, it is essential to collaborate with a partner capable of developing tailor-made projects through co-engineering. This approach creates a true synergy between customer and supplier, allowing the latter to capture the client’s needs and translate them into bespoke, purpose-built solutions.

At Vemek, a leader in the production of foundry supports, we fully recognize the crucial role of molds in the manufacturing process. For this reason, we consider them a core element of our work and an integral part of our commitment to providing customized solutions for all professionals in the foundry sector.

We are equipped with internally developed machinery designed exclusively for mold production — starting either from a core provided by the customer or from a 3D design.

Discover Vemek’s solutions for the foundry industry — a global reference point for the supply of supports and small metal parts for the foundry sector.