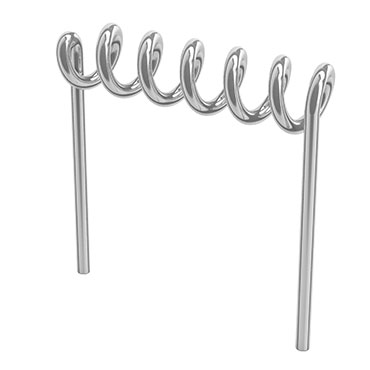

Shaped from soft iron wire with very low carbon content, the spiral coolers fo foundries amalgamate perfectly with the casting. Correctly positioned at the centre of the fluid mass to be cooled, they absorb part of the heat and speed up solidification, eliminating shrinking cracks and porosity during solidification. Available in a broad range of personalized shapes and sizes to ensure perfect cooling. Suitably shaped, they can prevent any interferences with subsequent casting jobs.

CONTACT US

CUSTOMISATION

Coolers for foundry are the ideal solution for problems of blowholes caused by shrinkage. Working with coolers means finding the perfect balance between the cooler casting (joining with the casting) and its ability to cool the casting from the inside.

It is essential to identify the most suitable type and mass for your casting. The form is also adaptable to avoid possible interference in subsequent processes.

TECHNICAL SHEET

| STEM | 1 Gambo | 1 Gambo | 1 Gambo | 1 Gambo | 1 Gambo | 1 Gambo | 1 Gambo | 2 Gambi | 2 Gambi | 2 Gambi | 2 Gambi |

|---|---|---|---|---|---|---|---|---|---|---|---|

| STEM DIAMETER | Ø 1,6 | Ø 2,0 | Ø 2,5 | Ø 3,0 | Ø 4,0 | Ø 4,5 | Ø 5,0 | Ø 1,8 | Ø 2,5 | Ø 2,5 | Ø 3,0 |

| SPIRAL DIAMETER | 10 | 10 | 15 | 18 - 24 | 20 - 25 | 20 - 25 | 25 | 8 | 10 | 12 | 16 |

| SPIRE NUMBER | 3 / 5 | 3 / 5 | 3 / 6 | 3 / 6 | 3 / 6 | 3 / 8 | 3 / 8 | 3 / 8 | 3 / 8 | 3 / 10 | 3 / 15 |

| TOTAL LENGHT | 75 | 75 | 100 | 120 | 120 | 120 | 120 | 40 | 40 | 60 | 80 |