In the foundry industry, the term scrap – or casting waste – refers to metal material that cannot be used, resulting from a casting or machining process that failed to meet the required specifications. There are many reasons why a casting may generate scrap: incorrect temperature, metal impurities, mold defects, or issues in material handling.

In this article, we focus on an often-overlooked yet crucial factor: the use of high-quality precision metal parts (core supports) that are preferably custom-made for the specific application. Components like core supports, spacers, or mold locators, when carefully designed and manufactured, play a key role in ensuring the stability of the casting process, helping to minimize defects and, as a result, reduce scrap.

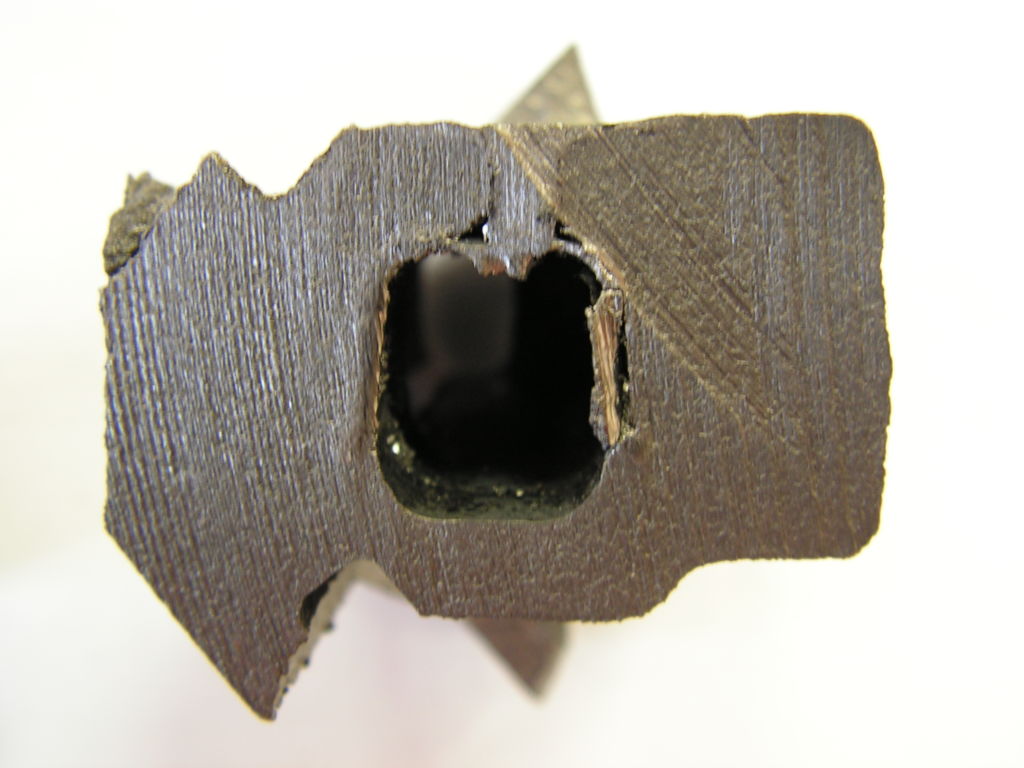

Defective castings

As one might expect, every foundry aims to minimize the number of defective castings (the ones that don’t conform to specifications). A casting is considered nonconforming when the final product doesn’t meet the project requirements, such as dimensions, tolerances, or material properties.

There are multiple causes that can lead to scrap: temperature errors, metal impurities, mold defects, or issues in material handling.

In particular, the risk of producing nonconforming castings increases with the pressure exerted by the molten metal on the mold walls and on the cores. This is especially true for pressure-tight castings, where the component must guarantee extremely high sealing performance. In such cases, even the smallest imperfections can result in a higher scrap rate.

The impact of foundry supports on scrap casting

The supports used to hold cores in place during foundry processes play a decisive role in the success of the casting. If the metal component is unsuitable, the support itself may fail, leading to serious issues—first and foremost, the undesired displacement of the cores. As a result, the final casting may fall outside the required tolerance range (that is, beyond the acceptable margin of error), or leakages may occur if the support is not properly integrated, allowing fluids to escape from the component.

Each of these scenarios leads to the same outcome: a casting that generates scrap material. How can these issues be prevented? Quite simply, by investing in the production of high-quality precision metal parts—and, more specifically, by designing custom-made supports engineered and manufactured for the specific application.

Choosing the spacer: an example of apparent savings and hidden costs

A foundry partnered with Vemek to develop a separator designed to maintain a constant distance between the water jackets of an engine. The client had to take a decision:

- A standard support, more affordable, but whose correct positioning depended entirely on the operator’s strength and precision.

- A custom-made support, slightly more expensive, but engineered to ensure perfect positioning and greater resistance to the pressure of molten metal.

The client chose the first option, aiming for immediate cost savings. However, during production, a problem quickly emerged: the support was often positioned incorrectly, compromising the proper alignment of the water jackets.

To solve the problem, the foundry had to install a highly specialized robot to check the height of the distance spacer and ensure it was correctly positioned inside the core. This intervention resulted in significant additional costs and greatly increased the complexity of the production process.

If the client had chosen the custom-made support, the additional investment of just a few cents per piece would have resulted in the following benefits:

- Correct and consistent positioning, with no need for additional interventions.

- Reduced scrap and fewer manual or automated inspections.

- Overall savings in time and capital, thanks to simpler and more efficient processes.

This example shows how, in the foundry industry, a choice based solely on initial cost can become more expensive in the long run, whereas a targeted investment in high-quality precision metal parts leads to greater efficiency, reliability, and a reduction in hidden costs.

Custom-made spacers made by Vemek

The risks of using low-quality supports

Before proceeding, it’s important to clarify that in this article, the term “low-quality supports” does not refer to solutions made from low-performance materials. At Vemek, quality goes hand in hand with customization: only custom-designed components, developed according to the specific characteristics of the casting, can effectively minimize the risk of defective castings.

Here are the main risks associated with using standardized foundry supports:

- Incorrect part sizing

- Reduced casting integrity due to supports that may fail during the process

- Uncertain raw material quality and variations between different supply batches

- Possible oxidation of the part beneath the coating (rust is the enemy of castings)

Low-quality supports: potential damage for companies

Experiencing scrap casting means facing a range of issues that can seriously affect a foundry’s operational reliability and its ability to produce lightweight, complex castings—a key requirement for staying competitive in the global market.

Producing foundry scrap first and foremost means failing to complete the job within the timeframe agreed with the customer. This, in turn, leads to…

- Increased expenses

- Delivery delays

- Loss of credibility

On top of these issues come additional waste of both time and money, caused by the need to identify and resolve the underlying problem.

Conversely, the use of custom-made supports makes it possible to produce castings with thinner walls—even just a few millimeters thick—resulting in a high-quality final product:

- Lower production costs

- Improved casting performance (reduced weight, hydraulic tightness, complex shapes)

- Increased company competitiveness

In conclusion, an investment of just a few cents per unit in foundry supports can generate significant competitive and production advantages for the foundry. These benefits become even more substantial when the project managed with customized supports is replicated over time and across larger production volumes.

It is also important to consider the inherent complexity of every casting project: when issues arise, simply identifying what caused the scrap requires a major investment—covering research, analysis, testing, and the implementation of a new solution.

Discover Vemek’s services for foundries — a global leader in the design, manufacturing, and delivery of casting supports.