Sixty years of experience, consolidated know-how, and product customization are the key factors that have enabled Vemek to insource a series of processes which, in the design of foundry chaplets, are usually outsourced to external partners.

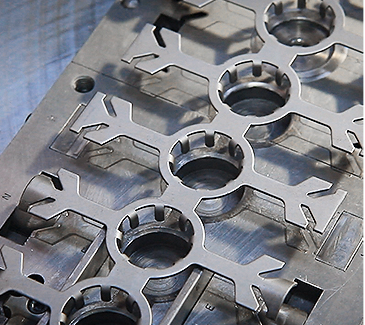

Example of molds for Vemek in-house production

At Vemek, we manage in-house the key stages in the design and manufacture of custom chaplets, conceived and developed together with the customer through a co-engineering approach. Specifically, in addition to the production related to our core business, we also carry out the following activities:

- Design and engineering of chaplets

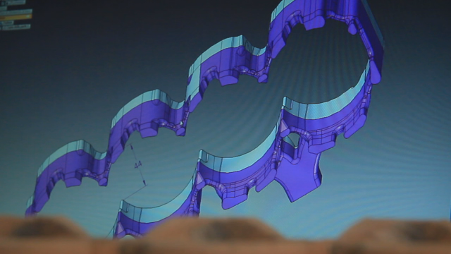

- Design of molds for sheet metal processing (carried out in a dedicated in-house tool shop equipped with CNC machines, wire EDM, 3D printers, and state-of-the-art design and control software)

- Riveting using machinery developed in-house

- Robotic assembly for process automation

- Tinning using two automatic lines

- Electro-welding

Vemek process insourcing and the benefits for the end customer

What are the benefits of process insourcing for the end customers using our products? We explain them below.

The more numerous and complex the activities that a production system manages in-house, the greater its control over the supply chain. This undeniable fact translates into a considerable number of advantages that, overall, impact the management of the entire process.

Indeed, process insourcing affects all managerial and operational aspects of production. Let’s look at them in more detail.

Mold design for Vemek in-house production

Quality control and inventory management

Producing in-house the individual components required to complete the production cycle allows the company to increase production volumes, while also building up stock, where appropriate, to be used promptly whenever needed. At the same time, it allows close control over each stage of the process, enabling prompt intervention to resolve technical and operational issues.

Let’s suppose, for example, that producing a single unit requires assembling several components manufactured by different outsourced companies. Even while remaining within the specified tolerances, it is possible that all the companies involved produce parts, for instance, at the upper end of the tolerance range. This can cause problems and delays during assembly, as variations of the same type are added together.

On the other hand, process insourcing makes it possible to prevent setbacks of this kind thanks to full control over the different stages of the process, for example, by intervening during the production of the last component to be assembled.

Direct management of each stage of the process also ensures significant operational flexibility, which is crucial, for example, to respond quickly to changes in demand or to minimize the risk of unexpected events. Having full control over the different process steps guarantees complete control of the supply chain, which in turn leads to a deeper understanding of the customer’s needs.

Communication optimization between customer and supplier

For the customer, the possibility of dealing with a single point of contact who can manage the different steps of the production process represents exceptional added value in terms of the customer–supplier relationship. The optimization of the communication flow brings with it several advantages, both organizational and productive.

Let’s imagine, for example, that the customer needs a new component that cannot be manufactured by their direct supplier. In this case, the manufacturer has to contact a new supplier, gather all the information needed to start the new production process, pass it on to the customer, and wait for their approval to proceed.

This kind of three-way communication leads to significantly longer lead times and a loss of operational efficiency. In production processes where the different stages and all components are managed in-house, this type of issue is avoided right from the design phase.

Cost and lead time reduction

Cost reduction is a crucial factor in favor of process insourcing. A production system based on external collaborations is more expensive, as each stage of the supply chain includes the supplier’s profit margin. Insourcing, therefore, proves to be the most cost-effective solution, also considering the elimination of transport and storage costs associated with external procurement.

Not only costs, but also production times are significantly reduced in an insourced system. Here too, an example can help clarify this.

When a customer requests a quotation, a production system based on outsourcing involves a complex and time-consuming pricing management. The company that deals directly with the customer has to wait for responses from the various external suppliers, analyze the different proposals received, and integrate them into a single offer. This inherently cumbersome process significantly slows down response times to the customer.

Similarly, the start of production is constrained by external suppliers’ lead times. Production can only begin once the materials have been received and the semi-finished or raw materials have been checked to ensure they meet the customer’s requirements.

Furthermore, any issues in the outsourced stages require additional steps: getting back in touch with the supplier, placing a new order, repeating the instructions, and, finally, restarting production. This chain of events not only extends production times but also increases the risk of errors and delays, ultimately compromising customer satisfaction.

Quality of the final product and know-how development

Being able to keep direct control over the entire production chain inevitably has practical and managerial implications that directly and positively influence the quality of the final product. A close relationship with the customer, a holistic view of the entire process, and the consolidation of in-house expertise all have a direct impact on production efficiency, on how unforeseen events and errors are handled, and on the optimization of processes and machinery. Indeed, insourcing allows the supplier to know the customer’s requirements in detail and to deliver products that are perfectly aligned with those needs.

Lastly, the skills factor is no less important. A company that can independently manage every stage of the production process develops a very high level of know-how and an overall vision that makes it extremely responsive, able to anticipate potential issues, and highly effective in problem-solving.

Although they are difficult to translate into strictly practical terms, these elements represent an exceptional strength both for the company operating in its target market and for the end customer.

The benefits of process insourcing in brief

Full control of the supply chain:

- In-house management of every stage for maximum quality and flexibility

- Accurate quality control and efficient inventory management, avoiding delays

- Immediate responsiveness to demand fluctuations and unforeseen events

Optimized communication:

- Simplified customer–supplier relationship

- Elimination of three-way communication loops and unnecessary downtime

Cost and lead time reduction:

- No external suppliers’ profit margins

- Reduced transport and storage costs

- Faster response times for quotations and production

- In-house management that prevents delays caused by external procurement

Quality and know-how:

- Direct control over production to ensure products meet customer requirements

- Development of in-house expertise and effective problem solving