We produce as if we were the customer. From the very first contact, Vemek activates a specific procedure, aimed at dealing with the problems and requirements which have been identified, with the goal of finding the best solution and meeting the objectives. Constant feedback between the Vemek and Customer allows us to obtain a rapid, positive and efficient development which starts from planning, design and construction of the necessary machinery, up to and including the manufacture of the end product.

Each project is different. But full customer satisfaction must always be ensured. The ability to design and create machinery and systems completely within our facility is one of the strengths of the company and makes Vemek the ideal partner when developing any project.

To support you in your ideas and products we can provide you with our experience, matured over 50 years of business, in close cooperation with the world’s most prestigious car manufacturers. This cooperation will lead to a metal part beyond compare, produced with the best dedicated equipment, with the highest quality levels and minimum costs.

Our problem solving process is composed of the following steps:

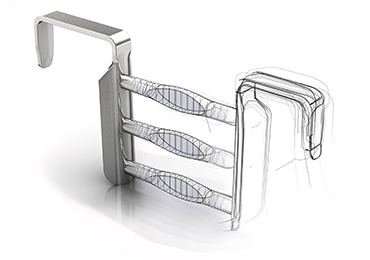

Your idea, first and foremost! A draft, a sketch, a drawing… That’s our starting point, after which we propose and address with you the most suitable solutions and equipment for the future mass production. At times, the small details lead to the biggest improvements and most significant reductions in production costs. This is the most exciting stage, where everything is possible, but where the groundworks are laid for the production to come.

There must be a good knowledge of technologies and equipment, so that they can be selected and adapted to the project, to the future quantities, to market needs,.. whether we are talking about chaplets for foundries, an electronic part, or a small precision part, this is the stage in which we want to be involved.

Once all the standards and required features have been defined, when the technical drawing has been completed, then this is the time we confirm the entire production cycle, which can of course differ from the sample stage and that of mass production.

This is an important stage, to be carried out together, so we can once again find the best possible solution.

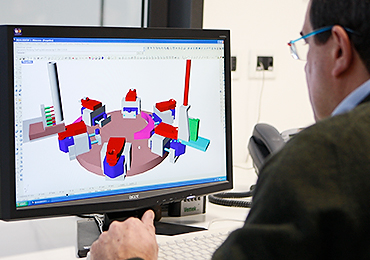

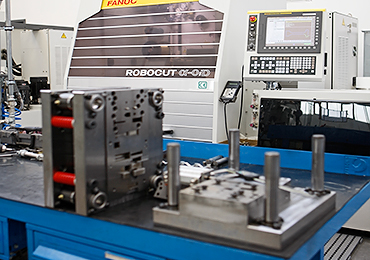

Once everything has been defined, we take care of it all. We plan and design the equipment, and we manufacture it. Our own mechanical workshop is fully equipped for the manufacture, detail and maintenance of machines and dies. Costs are extremely contained as we don’t need to outsource. We have the most modern 3D design software available as well as CNC equipment, wire electro-erosion, turning, grinding, milling and whatever else technology provides us with in order to manufacture the machinery. All of these stages are controlled and fully respect the agreed schedule.

Of course production is the fundamental step in translating words into actions. This is when ideas are formalised and take shape. We have been manufacturing for more than fifty years and we take the greatest care ofevery step.. All the stages are calibrated for your project.

SQS certifications are a source of pride for us at Vemek and ensure an ad hoc management system certified to guarantee maximum precision in all the production stages and 100% observance of the production requirements.

Tinning, checking and packaging. These stages, just like all the rest, are carried out within our facility, so that nothing is left unchecked. We use statistical checks and 100% checks, using automatic go-no go systemsdesigned specifically for your part.

We understand the importance of shipping and we know that it can make all the difference. Timing, robustness, speed, quality and punctuality are indispensable for our shipments.

We take care of the packaging because we know that products need to be protected if they are to arrive intact. Together, we decide the type and quantity per box, combining the best materials and the best technologies, to ensure parts are fitted quickly and easily into your production lines, and storage which adapts to your warehouse. We take care of the documentation and certifications. We select the best transport companies, the most reliable and the fastest because knowing how and when you will receive our products is a fundamental part of the product itself.

Your opinion is of utmost importance to us. Each stage of the production cycle can still be adapted and modified. That’s why we need your feedback. We need to know how our products are performing. Knowing what your warehouse staff or the end user think is essential.

It is from these exchanges of information that elements of extreme importance can come to light to complete the philosophy of constant improvement which has always set us apart from our competitors.